Cold Flow Capabilities

Properly managed, high-quality biodiesel blended fuels are successful in the coldest of climates.

Today’s biodiesel meets stringent national fuel quality standards — including the BQ-9000® fuel quality program and ASTM fuel specifications. By ensuring that your biodiesel meets these standards, and by understanding how to manage biodiesel in cold weather, you can use biodiesel year-round.

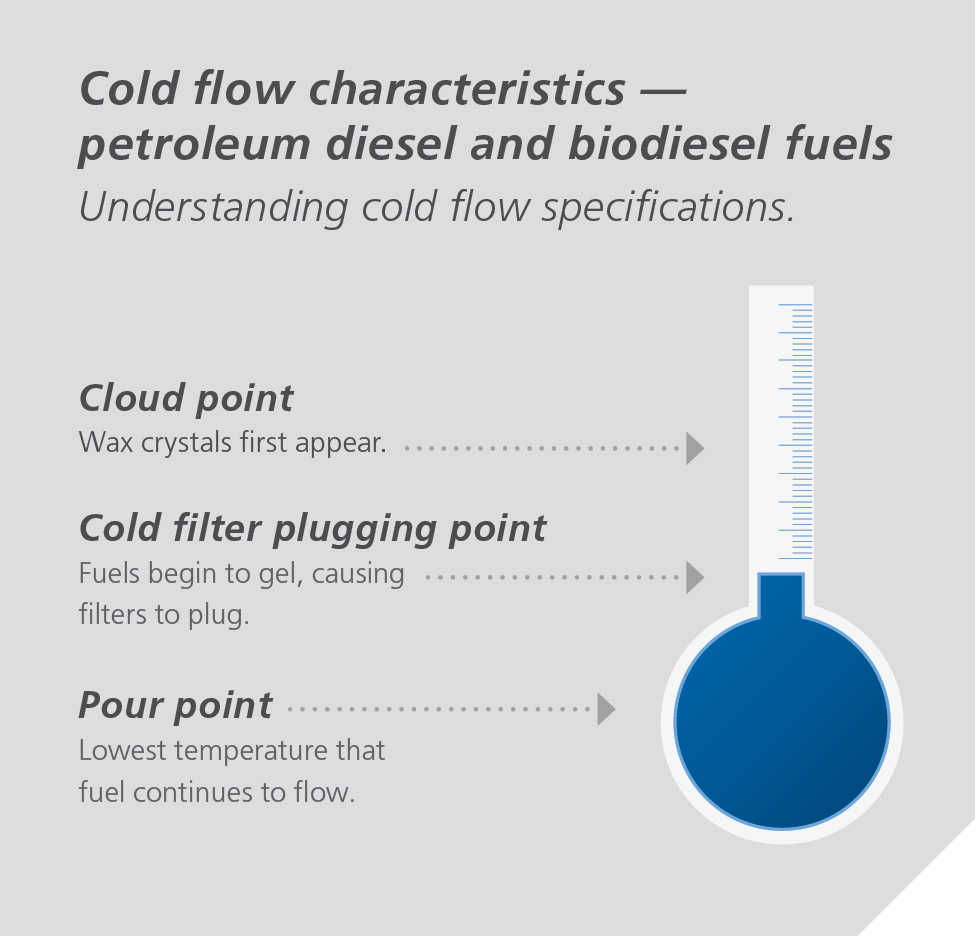

Diesel fuel and cold temperature characteristics.

Cold weather can affect the cold flow properties of both petroleum diesel and biodiesel. Just like No. 2

ultra-low sulfur diesel (ULSD), biodiesel can gel in very cold temperatures — so it’s important to take

the characteristics of both into consideration when blending fuel for cold weather use.

Managing your cold weather biodiesel blend.

Biodiesel blends of 5% and below have virtually no impact on cold weather operability.

While it’s true that pure biodiesel has a higher cloud point than No. 2 ULSD, blends of 20% biodiesel can be successfully managed using additive packages much like those used for petroleum diesel.

Tips for using winter additives with biodiesel blended fuel.

- Winter additives are an effective way to minimize winter operability challenges with standard diesel and biodiesel blended fuels.

- Be sure to use a quality winter additive that is designed to meet the needs of biodiesel blended fuel. (Additives that are successful for 100% petroleum diesel may not be the right solutions for biodiesel blended fuel.)

- In-line blending is best for cold weather additive success.

- Introduce the additive at a temperature that’s high enough to ensure both the fuel and the additive flow easily.

- Bulk fuel that’s colder than the additive’s handling temperature can chill the additive and prevent good mixing.

- Introduce the additive while the fuel is in motion. If the additive is more dense than the fuel, add it to the top of the tank. If the additive is less dense, add it to the bottom of the tank.

Case Study

In 2013, the city of New York established a requirement that its diesel-powered municipal vehicles burn a B5 biodiesel blend year-round. During fiscal year 2014, the city used 13 million gallons of biodiesel blended fuel. The Parks Department began to use B5 in vehicles throughout the city, before moving on to B20 blends. For more than six years, the Parks Department has used B20 as the standard fuel in its 850 diesel-powered fleet vehicles. Today more than 9,000 diesel-powered vehicles throughout the New York City fleet use a biodiesel blend.

LIKE WHAT YOU READ?

Chevron delivers insightful content like this to your inbox in our e-newsletters. Sign up today.