Midwest Renewable Biofuels Case Study

With biodiesel, the focus is often on the end product and its ability to significantly reduce greenhouse gas emissions in the vehicles that use it. The way the product is made, however, is just as important when accounting for the full lifecycle of emissions.

Midwest Renewable Biofuels Founded: 2012

Headquarters: Prairie City, Iowa

Operates: Iowa and surrounding states

Driving the circular economy

As its name suggests, the circular economy is a continuous process. But it has to start somewhere.

Midwest Renewable Biofuels is one of those starting points.

"Midwest Renewable Biofuels collects used cooking oil from restaurants and other locations, we clean the food and water out of it, and we deliver it to Chevron to be made into high-quality biodiesel,” says Joe Kooker, Operations Manager

at the Iowa-based company.

Contributing to circularity

With biodiesel, the focus is often on the end product and its ability to significantly reduce greenhouse gas emissions in the vehicles that use it. The way the product is made, however, is just as important when accounting for the full lifecycle of emissions.

Biodiesel production contributes to the circular economy by converting oils and fats, frequently considered waste byproducts from other industries, into a high-quality, cleaner-burning fuel that can be used in any diesel engine.

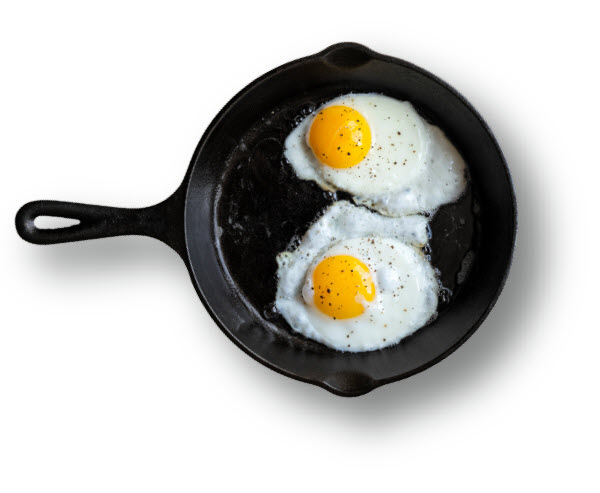

Used cooking oil is a great example. This is the yellow grease — think french fry oil — that comes from restaurants and other food production sites. In the past, it’d be sent to a landfill. Now, it can be recycled into an alternative

fuel.

This process alone — the circularity of it — is environmentally friendly, but it turns out that used cooking oil generally creates the cleanest type of biofuel possible and one of the lowest-carbon fuels of any type, making it one of the best

options for fleets to reduce their emissions right now.

Supporting local economies and the environment

Midwest Renewable Biofuels plays a key role in the process. The company was formed a dozen years ago by owner and President Dan Wilson in the small town of Prairie City, Iowa, with him as the sole employee. Now his crews collects more than 7 million pounds

of used cooking oil per year from restaurants, bars, schools, amusement parks and other locations throughout Iowa and the surrounding states.

“Used cooking oil starts out as the dirty part of the biodiesel world,” Kooker says. "When we collect it, it has food particles in it. It has water in it. We bring it back to our facility and clean it up and deliver it to Chevron Renewable" Energy

Group."

All of their product goes to the Chevron biorefinery in Newton, Iowa. There, Chevron cleans the feedstock even more before turning it into biodiesel. At the end of the production process, the fuel is delivered to locations throughout

North America where truck, bus, construction and other fleets use it as a replacement for petroleum diesel.

"The biodiesel industry supports farmers, local businesses and local communities by taking a waste product and turning it into something that’s good for our environment. The partnership between Midwest Renewable Biofuels and Chevron is great,”

Kooker says. "The biodiesel industry supports farmers, local businesses and local communities by taking a waste product and turning it into something that's good for our environment."

Making this type of contribution is one of the things Kooker likes best about his job.

“It makes me feel good about coming to work,” he says. “It may seem like a small piece of a bigger picture, but if I can take something that would otherwise end up in a landfill, turn it into fuel, and do something good for our environment,

that does something for me.”